Successful Cases in the Cosmetics Industry (Kajalan)

Customer background

Kajalan (Hong Kong) Group Company, born in the beautiful city of Guangzhou, has two major brands under its umbrella: Kajalan and Kevlar.

Kazilan has established a modern production base of over 50000 square meters and established over 15000 supermarket outlets in nearly 400 cities across the country; Established in 2001, after 17 years of continuous development, it has grown into a domestic lottery company

Makeup brand first; In 2016 Makeup Week, offline stores achieved a sales record of 7.5 billion yuan.

Customer difficulties and needs

Smuggled goods

There is no effective way to manage smuggled goods, which is greatly affected by the sales of smuggled goods by distributors, and the discovery of smuggled goods sales cannot provide strong evidence

Anti counterfeiting

Without anti-counterfeiting functions and control methods, products are heavily counterfeited by unscrupulous merchants, and the market supervision of counterfeit goods is not strong.

Warehouse

Manual counting during inbound and outbound operations is prone to errors, and the progress information of inbound and outbound operations is not transmitted in a timely manner. Manual data entry is prone to errors, and occasionally there may be situations where the wrong goods are sent

System

There is no software system for managing anti-counterfeiting functions, and collaborating with other companies to manage anti-counterfeiting functions has significant limitations.

Solution

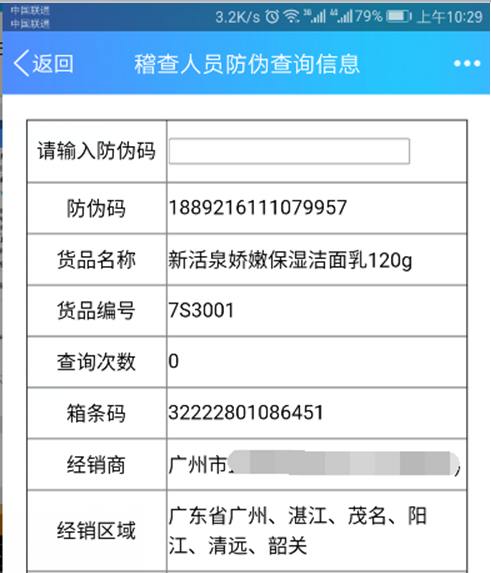

Improvement of smuggled goods

The management of counterfeit goods circulating in the market is convenient, fast, efficient, and accurate. Inspection personnel can use their mobile phones to complete the query of counterfeit goods

Anti counterfeiting improvement

|  |  |  |  |

Add anti-counterfeiting label query management to make it simple and convenient for consumers to conduct anti-counterfeiting queries. Enterprises need to accurately manage and control anti-counterfeiting code data.

Warehouse improvement

Accurately manage the quantity of warehouse inbound and outbound, making warehouse management barcode based and precise, and seamlessly integrate with the UFIDA U8 system for development

System improvement

Enterprise independent management and operation of anti-counterfeiting and anti smuggling management system, which can quickly trace products when problems occur

Improve the efficiency of traceability queries

Post launch effect

|  |  |  |

product Each product is labeled with anti-counterfeiting tags | production line Scan code packaging association operation on the production line | production line Production line process information record | labeling Labeling products and packaging boxes |

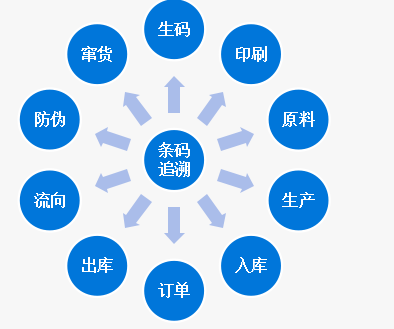

Through the system, unique barcodes can be traced, including anti-counterfeiting code sources, printing, raw materials, production, warehousing, outbound, orders, flow, anti-counterfeiting, and counterfeit goods. The traceability cycle is very short, which is conducive to enterprises quickly finding problem points and taking corresponding solutions

Try Now

Try Now