3000C barcode warehouse management software

Business background

China South Locomotive&Rolling Stock Corporation Limited was established with the approval of the State owned Assets Supervision and Administration Commission of the State Council, jointly initiated by China South Locomotive&Rolling Stock Corporation and Beijing Tiegong Economic and Trade Company.

As of the end of 2012, China South Locomotive and Rolling Stock Corporation Limited had 18 wholly-owned and controlling subsidiaries located in 11 provinces and cities in China, with nearly 90000 employees.

China South Railway Rolling Stock Corporation (CSR) has a complete system of independent development, large-scale manufacturing, and standardized services for railway locomotives, passenger cars, freight cars, high-speed trains, urban rail transit vehicles, and related components.

China South Locomotive&Rolling Stock Corporation Limited achieved an annual market share of 62% in the subway vehicle market from 2007 to 2010.

Customer difficulties and needs

Goods

There are numerous types of goods and chaotic management

Send out goods

Wrong shipment, reshipment, or missed shipment

Warehouse

The efficiency of inbound and outbound inventory is too low, inventory is inaccurate, and inventory is squeezed

Statistics

Every month requires manual verification and data calculation, which wastes time

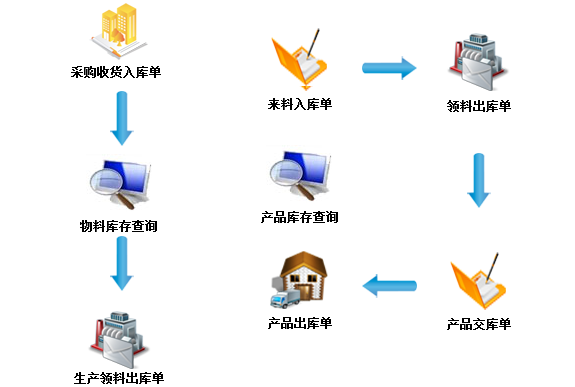

Solution

Product management

Batch import through fixed Excel table format

Classify and manage goods based on their type, number, and name

Can quickly query the detailed information of goods

Warehouse management

Using a data collector for scanning in and out of the warehouse, the point operation is precise and error free

Real time synchronization of information between data collectors and servers reduces the workload of warehouse personnel entering document data

Real time data synchronization allows relevant departments to monitor the progress of product inventory in real-time

Real time verification during outbound scanning to prevent the warehouse from sending the wrong goods

统计分析

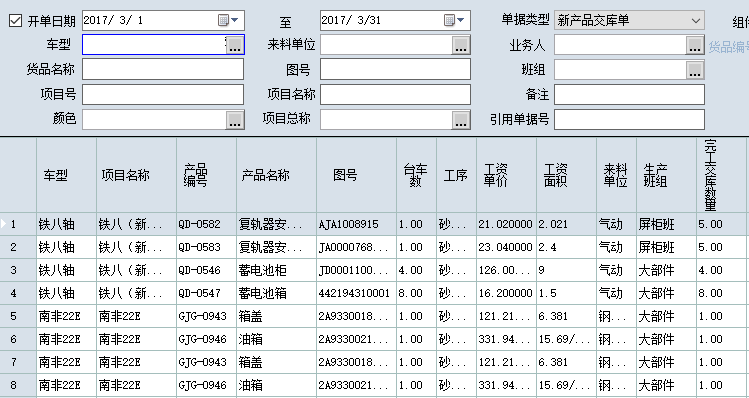

Statistics can be compiled based on the types of inbound and outbound documents

Can be counted by time period

No need for manual recalculation

Online effect

Product management

Easy import of product information

Unified management of product information

Solved the problem of chaotic management of product information

Warehouse

Follow a fixed process to avoid unclear division of responsibilities

Effectively prevent resending, wrong sending, and missing sending

Effective supervision of non-standard inbound and outbound operations by operators

Statistical analysis

Strategic data provided by various statistical analyses to administrators

Effectively improved the company's corporate management level, enhanced the image and grade of products

Inventory statistics

Relevant personnel can check the inventory quantity at any time

Each type of document has a statistical report

Can query which process each product is going to and how many items are in and out of that process

Try Now

Try Now